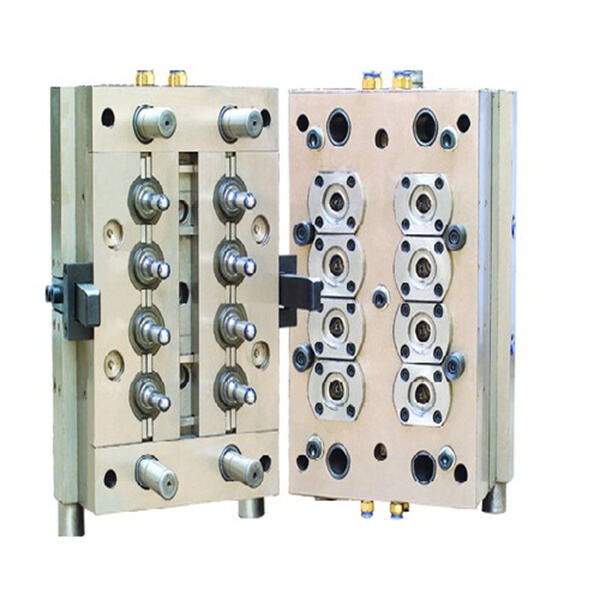

A specific kind of mold is the pet preform molds which are designed to produce plastic bottles in different shapes and sizes. Molds have significant importance in the packaging industry. The Preform Mold are used to make the bottles that hold beverages such as water, soda and juice, as well as sauces and other liquids we use on a daily basis. Without these molds, there would be no plastic bottles on store shelves.

The use of special machines that shape metal into molds. These molds are then used to manufacture the plastic bottles, which we use in stores in other machines. Creating these custom molds is a complicated and challenging process. But ensuring that the bottles are properly constructed and can contain the liquids inside without leaking is exceedingly critical. The molds must be exact, so that the bottles will be strong and safe to use.

Pet preform molds play an essential part in the packaging industry. The pet preform blowing machine help ensure that the bottles are the right shape and size. If the molds are poorly fabricated, the bottles can leak or break. This can lead to huge headaches for the manufacturers who produce the bottles and the consumers who purchase them. It may result in lost products and displeased consumers. This is why we need to choose a trusted supplier (WATON pet preform mold). They have expertise and made a great reputation for delivering quality molds.

Here are some essential factors to consider when you are selecting a pet preform mold supplier. Next, is look at the reputation and experience of the supplier in the industry. You need to choose a preform moulding machine supplier, such as WATON, with a track record of supplying high-quality molds with which customers are satisfied. Level of customer service from supplier is another thing to keep in mind. If you ever run into issues or have questions about your molds then it is very advantageous to work with a supplier who is willing to assist you. Finding a provider who gives you good customer service can mean a lot.

It is very important to care for your pet preform mold in order for it to serve you long and continuously produce high-quality bottles. A determined step in caring for your mold is to do its cleaning regularly. This also helps eliminate any dirt, residue or buildup that may negatively impact the quality of the bottles it produces. And you should examine your mold frequently for signs of wear and tear. If you see any issues, it is vital to deal with them promptly to stop larger problems down the line. How Your Mold Works More Effectively for a Longer Time with Proper Maintenance

Pet preform mold design structure has many new ideas that have speeded up the cycle of manufacture in the packaging areas. One of these is 3D printing molds. Manufacturers can create molds that are more precise and efficient than the ones used earlier due to this technology. Molds can be built quickly with 3D printing, and using significantly less waste saving money and production time. Other innovations are using new materials and special coatings that can help make the molds last longer and produce higher-quality bottles.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy