Preform blow molding is a really innovative and fascinating way to create various objects! This is a technology you can make plastic bottles, containers and many more products that people use daily. Dive into how the process works and see why it’s such a cool way to make things.

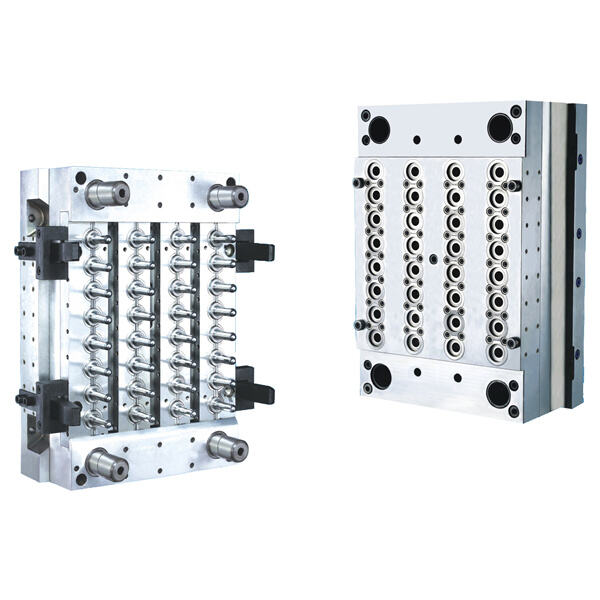

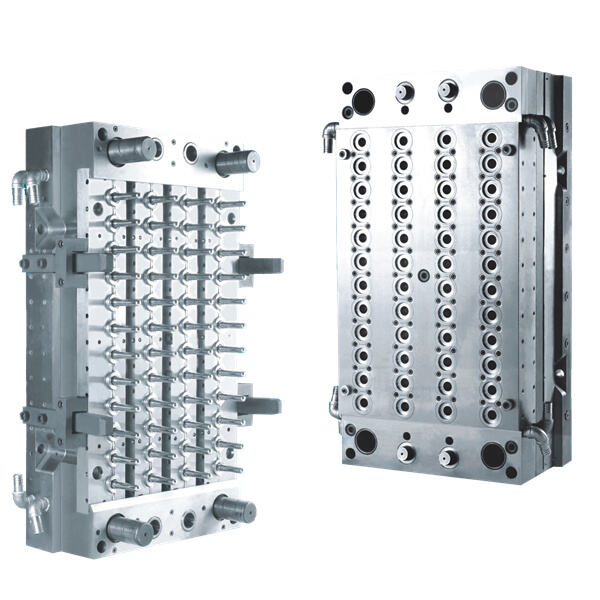

Preform blow molding is a specific technique used to create hollow objects from plastic materials. They start with a tube of plastic called a preform. This preform is then heated until it is soft. Then, they blow air into it and it expands into a mold. This mold serves as a kind of container that will shape the preform into its desired final shape. This process is used by many different industries to manufacture products we see and use every day, from those bottles of water to those containers for food.

Preform blow molding for product making has various such reasons. The two main reasons it benefits you are it saves you money on item production. The result also means that the process can be automated, with a machine doing much of the work, helping to save time and reduce the amount of workers needed. The companies can better design their products in an easier way and much faster. Prepform blow molding also has another excellent thing going for it, in that it can be highly customized. So, manufacturers can produce products in a wide variety of shapes, sizes, and colors, which makes it simple to fulfill the demands of their customers.

Preform blow molding is the best option for high-quality products. This technique provides the ability to well regulate the thickness of the plastic in the final product. Preform blow molding creates solid but durable and long-lasting products. This control is achieved in the manufacturing process, making these products consistent in quality, which is an important factor for customers who want reliable items.

There are innumerable products made with preform pet preform blowing machine in many different industries. (given that most plastic receives no or very little secondary treatment). One prevalent use is for producing bottles, including, for example, drinks like soda or water or household items like cleaning supplies. Another application of this process is forming containers for food or personal care products such as shampoo or vehicle parts. Preform blow molding also allows for the manufacturing of so many various kinds of products, making it a popular option for top manufacturers.

If you are considering preform semi automatic pet blowing machine for your manufacturing ventures, pay attention to the following tips to make sure you are successful. Firstly, only ever use quality materials and mold. It is important for getting the best results and for ensuring that your products come out correctly. It also matters quite a lot to ensure that you maintain and calibrate your machines. Avoiding potential issues that can arise from on-the-spot production is a big plus. Finally, partner with a good manufacturer such as WATON, who specializes in preform blow molding. They can offer you guidance and assistance to help you obtain a quality result.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy