What is a Preform moulds and why is it so crucial? These tools shape objects like bottles and jars. There is a reason why this is the second most widely used type of glass packaging in the world imagine attempting to produce a bottle without a mould! It would be extremely hard and take a very long time. This article will discuss the importance of preform moulds, how they make the process faster and better results, the various kinds of preform moulds, the benefits of using preform moulds in production, and some tips on how to select the one that works for you. Repeat process on preform moulds — which are special magic tools that transform a plain tube of plastic into bottles or jars.

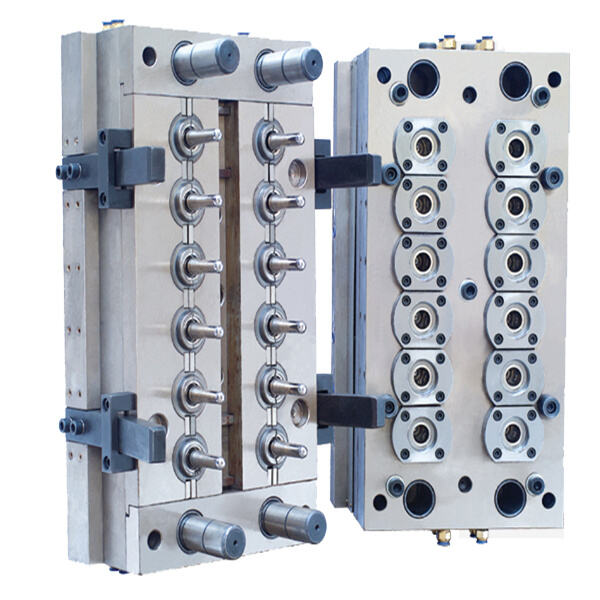

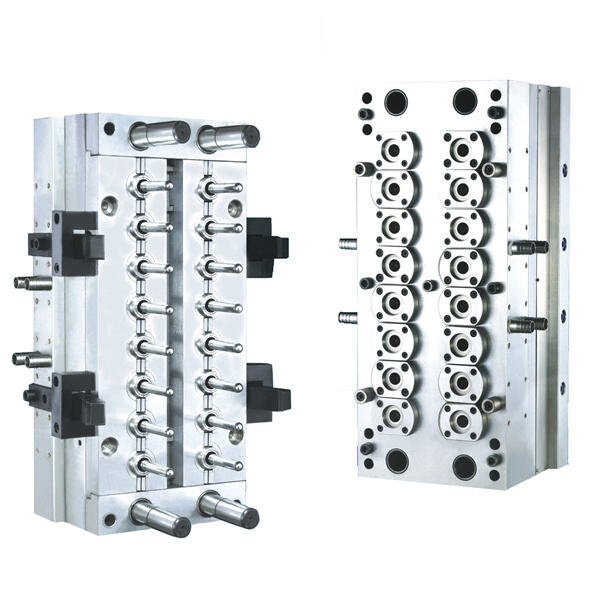

These moulds are rigid, constructed using strong materials like metals, which ensures their longevity. It is designed to produce the same flawless shape time and again. Most of the bottles and jars we use in our daily life would be almost impossible to produce without preform moulds! What if all the bottles were different? Typically they are employed to store phenol formaldehyde resins and standardize the work process to obtain desired outcomes.

Preform moulds minimize labor to a large extent and increase production of these bottles (in factories). These assist factories in making each bottle or jar in the same manner, each time. This results in less error and quicker product readiness for sale. Instead of spending an excessive amount of time correcting errors, workers are able to focus on making more products. They can make hundreds of thousands of units in a short time using preform moulds. This is one of the reasons why preform moulds are a crucial component of this process. They help ensure that the manufacturing process goes on smoothly and effectively.

Preform moulds come in many different types for various kinds of jobs. There are certain moulds that create small bottles, while some moulds are meant to make large containers like jars. Preform moulds vary in size, shape and the material they are made out of depending on what they are being used to produce. A mould for a small bottle, for example, will bear little resemblance to a mould for a large jar. Certain preform moulds are capable of making unique designs or patterns on the final product. Preform moulds can be of different types; each one is used for a specific purpose for manufacturing, thus they are very useful tools.

Factories and manufacturers profited greatly from preform mould s. It saves both time and money, making production quicker and more efficient. Because you can make products faster with preform moulds, factories can use it to produce more products in the shortest time. In addition, they assist with guaranteeing each item is made the same way each time, which is extremely significant for keeping up high caliber in the items. Preform Moldhelp to reduce waste generated from the manufacturing process by producing a smaller rate of defective products. That is why factories are eco-friendly since they do not waste any raw materials. In general, the use of preform mould will promote higher productivity and higher profits for factories.

When selecting a preform mould for your production requirements, it is vital to consider a few aspects carefully. First, semi automatic moulding machine think about the size, shape and material of the product you’re making. The preform mould you select must be adequate for whatever you need to produce. Similarly, you want to ensure that that preform mould is made out of durable material and is going to last you for a long time. Explore the types of preform moulds available and select what best suits you. We also keep the cost in mind, because preform moulds can get really expensive. Asking experts in the field to help you choose the right preform mould for your production needs is always a good idea. They should help and come with useful advice.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy