Stretch blow molding machines are special machines that can make many different plastic bottles and containers. They can commonly be found in factories where they manufacture objects such as soda bottles, water bottles, and soap dispensers. A typical question is it possible for these machines to run different weights of PET preforms. So let's get to know these machines, and how they interact with different preform weights.

INVESTIGATING STRETCH BLOWING MOLDING MACHINES

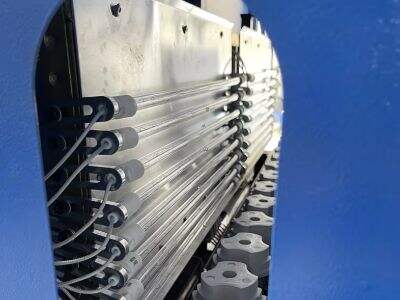

WATON stretch blowing machines are highly adaptable to various needs. They have the technology to run various sorts of PET preforms. That means they can process preforms of a range of weights without causing any difference in the quality of the produced bottles.

Breaking Down PET Preform Weights

PET preforms can have varying weights depending on the size and shape of the bottle or container. Some preforms are light, and some are heavy. The stretch blowing moulding machine can adapt to these various weights by modifying its parameters. This helps ensure that when the game is done, it will be just right.

Can One Machine Handle Variable Weights?

Yes, one set of stretch blow molding machine can produce a variety of weight of PET preform. The machine can adjust its temperature, pressure and timing to suit the preform’s requirements. With the proper setup, the machine is capable of creating bottles and containers in many shapes and sizes with no trouble.

How to use Stretch Blowing Molding Machines

Here are some useful tips for a stretch blowing molding machine to do well for various preform weights. First be certain you have the machine adjusted right for the weight of the preform you are processing. This makes the stretching and blowing procedures function well. And be sure to regularly inspect and care for the machine to avoid problems that could interfere with your ability to use it properly.

Effect of Preform Weight on the Efficiency

The weight of the preform can have a significant impact on the functioning of the stretch blow molding machine. If the preforms are light or heavy, they might create trouble during the stretch-and-blow process. To keep the machine operating in sought environment an appropriate weight of preforms must be used and that machine is set up appropriately.