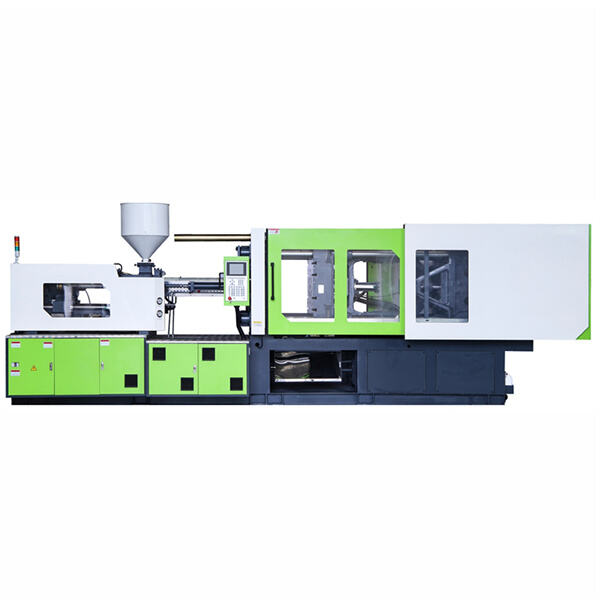

Plastic injection molding presses —specialized machines that produce large quantities of plastic products. These materials likely include everyday items, such as toys, bottles, and even critical components for automobiles. These WATON plastic injection molding machine are used in production facilities where goods are manufactured. We will take you through what specifically plastic injection molding presses are, how the process works, how you can select the right one for a project, some common applications for them, and the numerous advantages of utilizing these machines for manufacturing purposes.

Plastic injection molding press has large and powerful machines. It manufacturers plastic items by injecting molten plastic into a mold. A mold is like a unique form or shape inside the container. This is the form that the plastic will fill in, becoming the object we desire. After the plastic is injected into the mold, the machine needs to cool it. The plastic hardens when it cools down. Then we can open the mold and remove the finished product, which is the item we wanted to produce in the first place.

We have to make a mold for what we want to produce — in this case, something using a WATON blowing molding. This diagram is crucial because it dictates the form of the end result. Once our mold is ready, we place little bits of plastic known as pellets into the press. The machine then heats the pellets to a melted plastic. After melting the plastic, we then use an injection unit to push the melted plastic into a mold. The mold is then shut tight enough so that not a drop of plastic can escape. The mold, filled with warm plastic, is allowed to cool and solidify. Eventually, we can release the mold and pull out the finished product that was just created.

As a result, there are several key considerations when selecting a plastic injection molding press for a particular application. So the first thing we need to figure out is the size and shape of the thing we want to create. However, each object must use its specific type of mold. We also have to consider what we would be making the item out of. Everyone’s press works with different things and has different strengths, which makes it critical to find one that matches our needs. Case in point: If you need a press, WATON has all kinds of old and new. Let our team match you with the right one that will suit your exact project.

A wide variety of products are manufactured using plastic injection molding presses. Some of these are small, such as toys that kids play with, some as large as components for cars. These machines assist in producing food and beverage packaging, like bottles and food packaging. WATON large blow molding machine presses also play an important part in the medical field. They are used to manufacture things like syringes, which administer medicine, and IV tubes that deliver fluids to patients. Due to their flexibility, these devices can also be used for a wide range of purposes in many different industries.

Plastic injection molding press presents many compelling reasons to be utilized in manufacturing. But one of the greatest advantages is the speed at which they can manufacture a lot of things. This WATON injection molding machine allows businesses to save time and money while streamlining production. Plastic injection molding presses have another benefit, especially when used for plastics, where very high-quality products are formed. That is one of the reasons they are manufacturers' first choice for reliable and accurate products. Also, they consume less material to make a certain size of the product. Furthermore, they can recycle unused plastic and remake it into new products, which is more environmentally friendly as well.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy