If you take a look around you right now, you might spot a number of things out of plastic. Plastic is a durable, versatile substance that can be molded to various shapes and forms. You can even notice that some toys, containers and even parts of your used gadgets are made up of plastic. Plastic injection machine One of the machines that help create these plastic products is called a plastic injection molding machine. What did you just say? Dear Reader, Plastic injection machines: What they are and how they have transformed the manufacturing of products

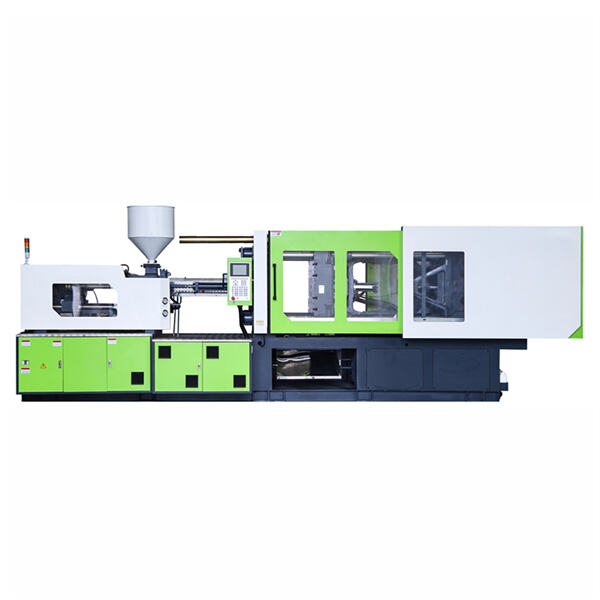

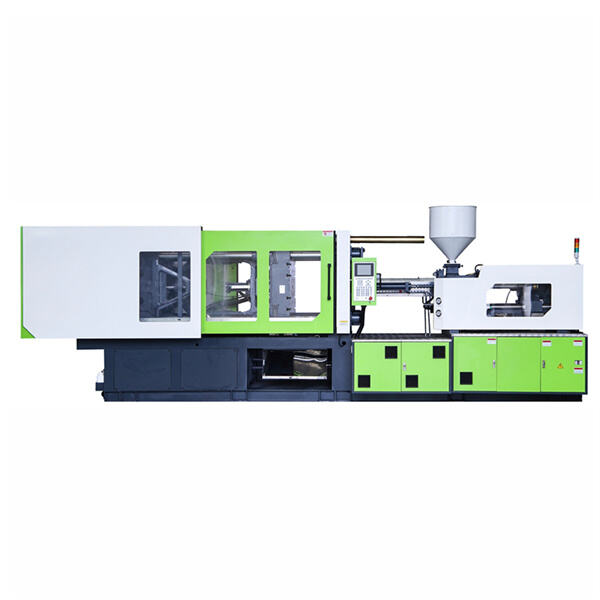

Plastic injection machine is a big and strong piece of equipment that is used to manufacture plastic products by injecting liquefied plastic into a mold. Imagine the mold like a giant cookie cutter — it shapes the plastic to the design we want. When the plastic cools and solidifies, the mold is removed to produce a finished and ready to use product. There are hundreds of other products that can be produced with plastic injection machines. They can make things like toy cars, kitchen utensils like spatulas, and even components for large industrial machines.

Before the advent of plastic injection molders machines, creating plastic products was very demanding and time-consuming. They had to literally shape the plastic by hand or use other machines that were time-consuming and not as effective. This all changed when the plastic injection machines were invented. Today, products can be produced with speed and precision with minimal room for error. This was a huge advancement for the manufacturing process since now there could be a large amount of the same plastic item created in mass production. As a result, we’re seeing more plastic products in shops and households than ever before.

In fact, there are some major considerations to keep in mind when selecting a plastic injection molding machine. Finally, think as [sic] the Size of your Products. Some machines are built to make small things, while others are more suitable for larger objects, such as big containers or car parts. Another plastic consideration in product design is what type of plastic will your products be made from? Some work better with certain plastic types, so make sure you get the right one. Lastly, consider your budget. How many does it cost for a plastic injection machine? I step through the important aspects to make sense of the machine that is right for you.

The plastic injection machine has several components that function together as a team to produce plastic products. First, small pieces of plastic called pellets are heated until they melt into a liquid. Next, the melted plastic is injected into the mold under very high pressure, so that it completely fills every cavity in the mold. Once that plastic cools and hardens, the mold opens and the final product is ejected. This entire procedure is done very quickly and can run several times in sequence. That means many plastic products can be continuously manufactured with little downtime.

There are various types of plastic products used in all sorts of industries (Plastic injection machine and their usage) based on the work of plastic injection machines. Take the car industry — they use it to create things such as bumpers, dashboards and even the little clips that hold everything together. Medical: Plastic injection machines are used to produce medical devices and equipment such as syringes and containers for medicines. In the food industry, similar machines are used to prepare the packaging for food products, including containers for snacks or bottles for drinks. There are numerous potential uses for plastic injection machines, and they are essential in making your daily lives easier.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy