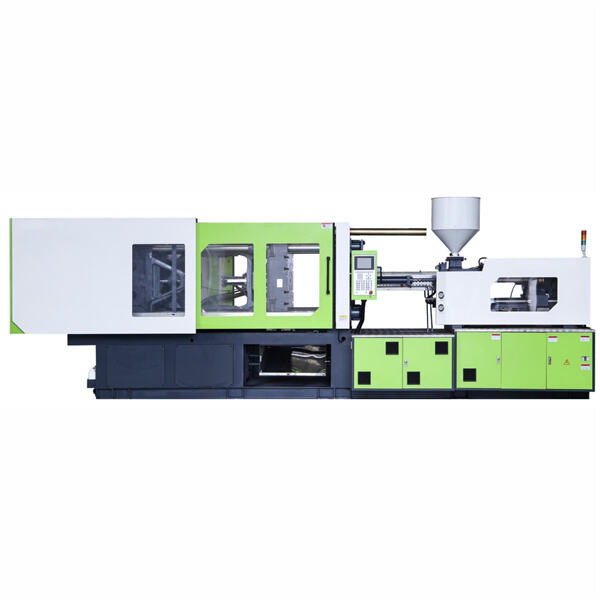

Let’s start with the several unique machines that manufacture the preforms used for plastic bottle production. Introducing WATON Pet Bottle Preform Making Machines. WATON announced the new technology which they were going to utilize to manufacture their Preforms. Preforms play a crucial role in its production as they are the initial building block of plastic bottles. The bottle preform making machine machine works by heating up plastic to a point where it becomes soft and malleable, which enables it to be shaped. The machine then shapes the now-soft plastic into the desired shape for the bottle. This process is also very important as it produces bottles that can more safely and securely hold liquids.

For The Second Step, let’s explore how these machines can form preforms in various shapes and sizes. The most powerful advantage of WATON machines is that they are highly flexible and versatile. This allows them to create preforms in many different shapes and sizes, depending on what type of bottle you want to produce. Whether you required a small preform for a small bottle like juice or a big preform for a big bottle for water, these machines can provide! This pet preform blowing machine flexibility also enables companies to produce a variety of bottle types to meet customer demand.

One of the greatest advantages is that the machines operate at high speed. So you can produce a lot of preforms in time – that helps you to speed up your production hands. This will enable your business to keep up with customer demand when you can create preforms at a fast pace. Because of the accuracy of the machines, you can also ensure that every preform will be identical. This is important consistency because it means better quality bottles, which is what customers want.

So, next, lets learn how these machines ensure every preform is produced in the same way and at a high quality. The WATON pet bottle preform making machine is not just a conventional machine; it is a very intelligent machine. The preform moulding machine come equipped with special sensing and control devices to check parameters such as temperature and shape. There are also these sensors that ensure every preform is precisely perfect. To get this right, and avoid errors in production, requires a high degree of accuracy. If every preform is perfect then every bottle will be perfect too.

Last but not least, to learn how a WATON pet bottle preform making machine can greatly improve your production efficiency. With the help of these sophisticated machines, you can produce high-quality preforms while speeding up your production process and minimizing waste. Waste reduction is good for your business — and for the environment. That all can add up to big savings over time. And, because these machines are so sturdy and dependable, you can rely on them to keep on going strong for years. If you want to make changes that will significantly improve your manufacturing process and efficiency, a WATON pet bottle preform making machine can work for the success and growth for your business.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy