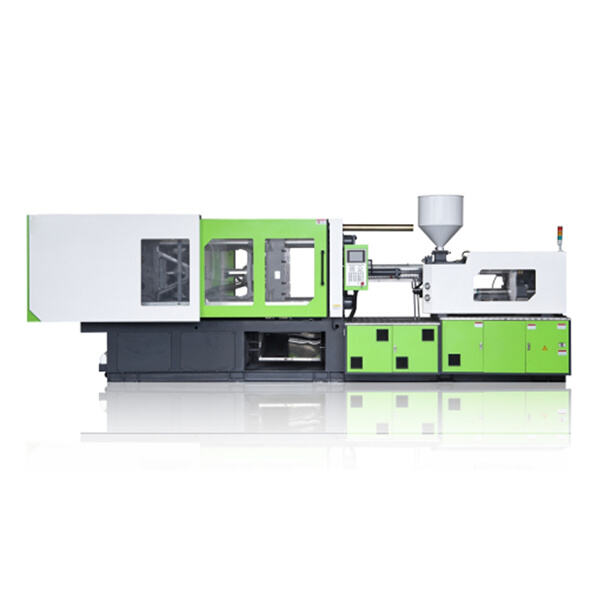

Injection molding is a unique process used for producing plastic objects. Through machines, WATON does this job nicely. These devices melt plastic, and can mould it into a variety of different shapes. So let’s take a closer look at how injection molding machines work and why they’re so integral to the production of many of the things we use every day.

Prior to the introduction of injection molding, producing plastic products was much more labor-intensive and required a lot more time. For instance, if a person wanted to create a toy, they would spend time molding the plastic by hand, which takes ages. But with injection molding, we can create a lot of products easily and fast. It has transformed the way we make things like toys, water bottles and even components that go into cars and airplanes. And WATON has been at the forefront of this major transformation, utilizing new and pioneering technologies to ensure the efficiency and quality of their semi automatic blow molding machine. So this sort of feature allows businesses to keep pace with the demand for plastic items, which is realistic in this fast-paced world.

Injection molding machine process is when small granules of plastic called pellets are melted down. Afterward, we inject melted plastic into a mold. A mould is like the casing of that kind of container which has a specific form on its inside. When the hot plastic takes the shape of the mold, it will cool down to fill in the entire filled area of the mold. This means that after this process the plastic adopts the shape of the mold. This process can also be repeated many times to produce numerous copies of the same object, be it hundreds of toys or thousands of water bottles. WATON's molding process is top-notch, ensuring that each manufactured item is its own perfect replica. People would want the same quality and level of products when they get them and this is where it is important also.

Using automatic pet stretch blow molding machine to manufacture products has a number of great benefits. Speed is one of the greatest advantages. This approach allows us to produce items significantly faster than other manufacturing processes. To exemplify, if hand-building toys took a week, injection molding might only take a day or two. Injection molding also provides for complex shapes and designs that may be difficult or impossible to produce other ways. This means designers can create toys in unusual shapes, and injection molding makes it all possible. It creates minimal waste, thus being easier on our planet.

Molding machine injection is capable of producing endless of things, with the aforementioned being just a few of them. WATON has experience producing for all those sectors and beyond, demonstrating the versatility and utility of this manufacturing method. Injection molding is an integral part of many industries, providing the products that we rely on.

It may look complex initially to operate a molding machine injection system, but you will get used to it the more you work with it. A very simple step-by-step process to explain how semi automatic molding machine works.

Now you know how molding machine injection works and why it is an essential element of modern manufacturing by doing these steps. With its pioneering product designs and high-quality supply chain WATON is actively shaping developments in the field.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy