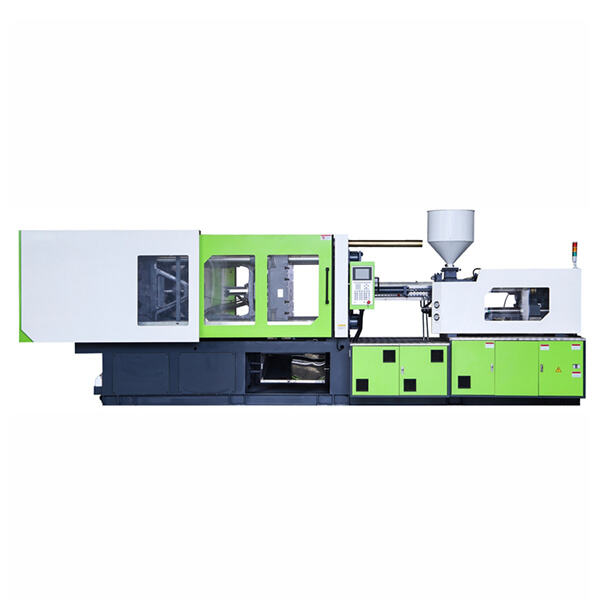

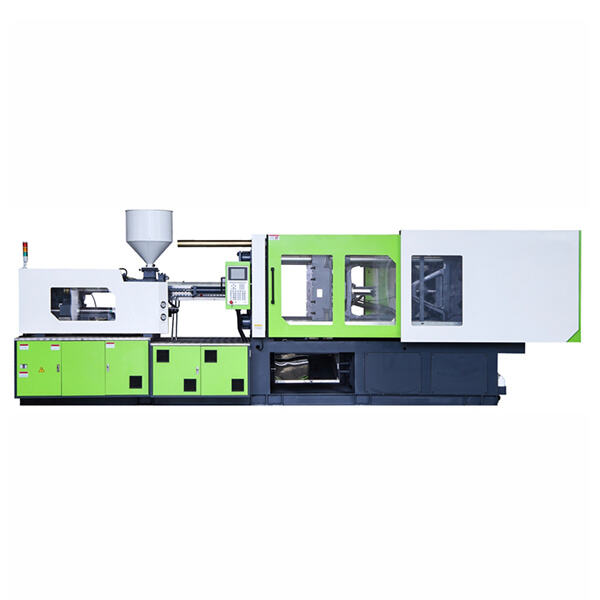

Plastic pellets, small pieces of plastic, are heated so they melt into a thick liquid to begin the process. The melted plastic is then injected with extreme pressure into a mold. This bottle preform making machine means the push of melted plastic into the mold by a machine happens at a very rapid and powerful speed. Then there is cooling down. When it hardens, it assumes the shape of the mold. Finally, the completed component is ejected from the mold. That allows manufacturers to efficiently produce lots of identical parts in a short time

They try to improve their injection molding machines for companies to create as many products as possible. Investing in advanced machinery is one powerful way to do this. These newer machines are usually faster, more accurate and more energy-efficient than older models. By making it possible for companies to produce faster, advanced injection molding equipment allows them to better fulfill their customers' needs.

Firms can argue it all the way, however may make it vastly reduce waste, when materials are by no means utilized effectively. This helps manufacturers to save money by SPENDING LESS and use the resources wisely. Additionally, with significantly improved finished products quality, customers tend to be more satisfied. This glass jar making machine allows the companies to remain competitive in the market because they produce better products at lower rates

There are several key factors to consider when searching for the right machine. Step 1: Consider the size of the parts you want to produce. Different machines digest different sizes, so it is important to select a machine that suits your needs. Next up, think about the material you are going to use. Understanding the different plastics and the techniques required for molding can help you make an informed decision when selecting equipment. Lastly, consider how many products you would like to create. You will need a machine that can output in high volume, if you require making many products at once. Choosing the right injection molding equipment is essential to achieving the most optimal manufacturing process.

Because there are a number of factors that need to be considered when deciding what injection molding equipment to buy for your factory. To start, think about the size and complexity of the parts you need to create. So, ensure the equipment you select can manage both the volume and your products’ specific needs. This drinking water bottle making machine entails confirming that the machine can manufacture parts that are not only correctly sized, but also fit any design specifications you may have.

Then plastic jar manufacturing machine consider what sort of material you will use. Factors: Different plastics behave differently during the moulding process and learning to work with these materials is important. Some machines are tuned to particular types of plastic, while others will accommodate a broader range. Lastly, think about how automated and precise you want your production process to be. And more sophisticated machines can complete a task autonomously, which can save time and minimize errors. So, If you consider these factors carefully, you will be able to choose the best injection molding equipment for your casting needs.

The following are some key things to know before investing in injection molding equipment. First, you need to know the injection molding process and its basic principles. And you will have enough knowledge to know what the equipment can do and what it may not be capable of. After that, investigate the plastic bottle manufacturing equipment different types of injection molding machines available in the market. Check out their features and to find ones that fit what you need.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy