The making of bottle caps lags greatly in importance to the bottle cap molds. Good molds that fit perfectly on bottles is essential and we at WATON know it well. And without these molds, it’d be difficult to make caps with a good seal that protects the contents inside.

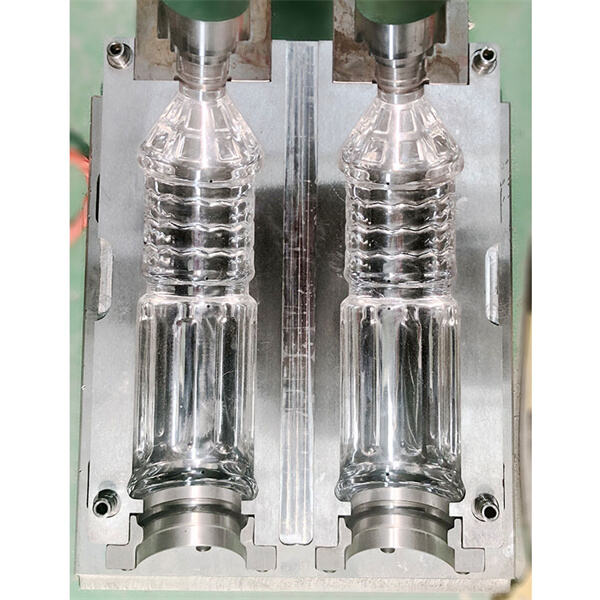

Bottle cap molds are created through injection molding, along with the automatic pet stretch blow molding machine. This involves injecting melted plastic into a mold, thus creating the shape of the cap. The mold itself is two parts that fit tightly together to form the cap. This forms a solid bottle cap because once the plastic cools it creates a strong and relibale shape of the mold it created. They use this method because you can make a lot of caps and do it fast and efficiently.

Here is a list of 5 things to consider when designing a custom bottle mold. First, you must consider the size and shape you want your cap to be. This is important because different bottles can require different shapes of caps. Yours seems to be in a space without a logo or text. These details are what make your bottle caps special and can help give your product an advantage in shelf presence. And here at WATON we have a team ready to make sure your mold is perfect for all your bottle cap needs.

Steel and Aluminum are the most common materials used for bottle cap molds for semi automatic molding machine. Each has it is own pros and cons. It is very strong and long-lasting, making it perfect for mass production as one mold can make numerous caps per year. Aluminum molds on the other hand are significantly lighter and easier to work with, which makes them ideal for smaller projects or cases that will require quick changes. Choosing the right material is important; it may impact the performance of the mold and the number of caps that can be produced.

Making bottle cap molds with semi automatic blow molding machine requires a great amount of quality control. At WATON we take this very serious and every mold we make must be according to our strict rules. Being strict at this point, helps us to overcome unwanted issues related to caps in future. A mold with defects can mean caps that do not fit or, even worse, lead to potential leaks — which we need to avoid at all costs. Our strict quality control is necessary to guarantee non-toxic and green caps.

Implementing proper maintenance of your bottle cap mold will make sure that it not only lasts for a very long time but also works well. That involves regularly cleaning it to get rid of any residual plastic debris or dirt. You should also store the mold properly, when you’re not using it, to prevent any damage. If the temperatures are too high the mold could bend or break and you'd lose it. If you follow these care tips, you can expect to keep your mold in beautiful shape for many years to come.

We warmly welcome OEM orders. With our advanced production equipment, skilled workforce and rich production experience, we have the ability to meet various OEM requirements. We can customize products according to your specific designs, specifications and packaging needs. Our dedicated team will work closely with you throughout the process, ensuring strict quality control and timely delivery.

Our strength lies in innovative design. With 20+ years experience, our team of professional designers is constantly keeping an eye on the latest market trends and customer needs. As a custom-made machinery processing factory, we have strong execution capabilities. The development cycle of a new machine model can be as fast as 1-2 months, including 3D modeling, custom processing, installation and debugging, and perfect delivery.

We are a factory-direct company, which means we can offer you products straight from the production line. By eliminating middlemen, we significantly reduce costs, enabling us to provide more competitive prices. This also allows for better quality control, as we have full oversight from raw materials to the finished product. You can be assured of getting high-quality products at factory-direct prices, maximizing your profit margins and satisfaction.

Our company shines with its exceptional after - sales service. We respond promptly, guaranteeing a reply to customers within 24 hours. Our service team, a blend of sales staff with excellent communication skills and experienced engineers, is fully committed. The sales staff adeptly understand customer concerns, while the engineers offer in - depth technical insights. Together, they efficiently solve all customer queries and provide comprehensive technical support, ensuring a seamless experience for every client.

Copyright © TAIZHOU WATON Machinery CO., LTD. All Rights Reserved Privacy Policy